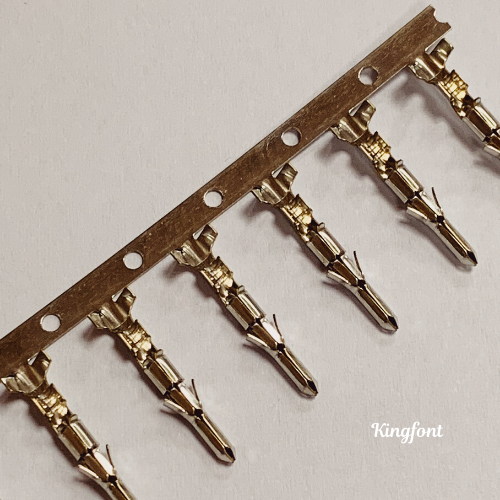

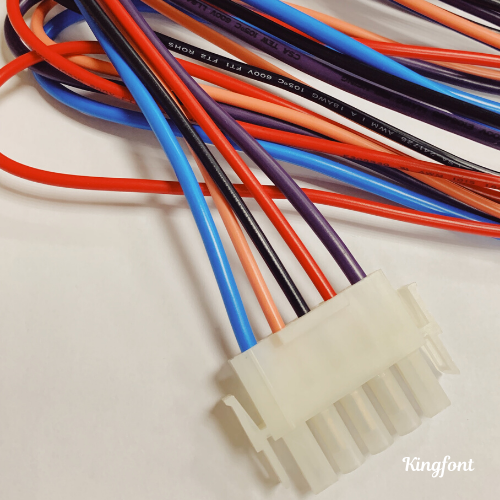

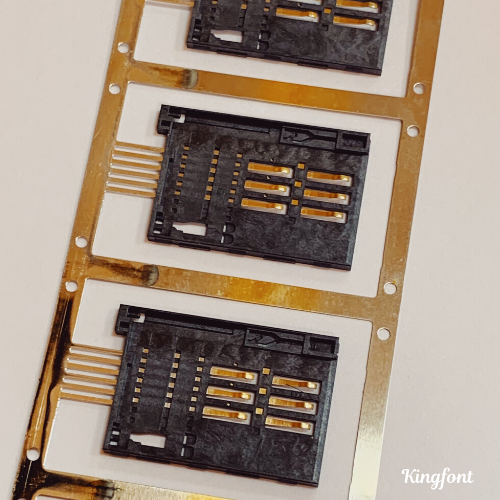

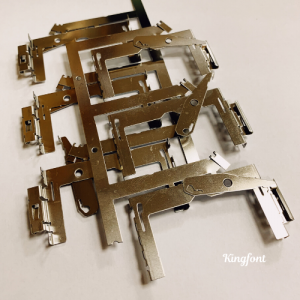

Kingfont’s main focus at its early stage in the 1990s is the R&D of progressive dies and optimizing stamping processes, along the way Kingfont also developed skills of cable assemblies and plastic molding, including over and insert molding. As it turns out, Kingfont has equipped itself with manufacturing stamping components and interconnects, due to its advanced die and mold making abilities for 37 years, which Kingfont has been having better command of today.

Because of its profound expertise, Kingfont team comes to have the talent to conjure and reach customers’ different design needs, making Kingfont one of the most renowned original equipment manufacturer (OEM) in Asia. What’s more, as an experienced interconnect supplier, Kingfont invested in the set-up of a CNLA and ISO17025 certified laboratory to guarantee overall quality of its products; the team also apply ISO 9001 and 140001 standards as its management principles.

In a nutshell, Kingfont provides quality connectors and stamping parts with competitive prices, conventional or inventive.